Product Assurance – Bespoke Fasteners

Blindbolt UK | 28th December 2021

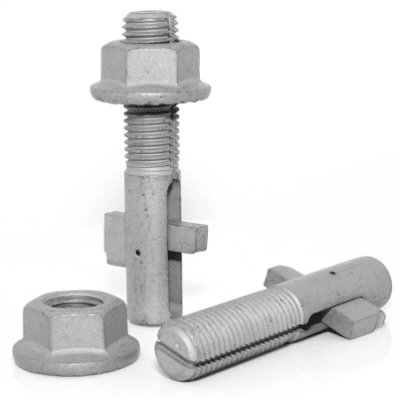

Blind Bolt

Standard Fasteners

Standard nuts, bolts and washers are manufactured in accordance with national or international standards and must be CE Marked when used in Europe (or UKCA Marking in the UK). There are no harmonised European standards for bespoke fasteners, which means specifiers must look for confirmation of their suitability and resistance by some other means. Where a harmonised standard does not exist, CE marking is still possible via a European technical Assessment (ETA) which is essentially a standard developed specifically for the individual product. Some manufacturers have followed this route.

Other manufacturers have chosen to have their product evaluated by ICC-ES, which is a North American equivalent to CE Marking. Both processes involve the specification of product performance requirements, testing programmes, analysis of results and audit of factory production facilities by an accredited independent body.

Whilst progressing their formal accreditation, some manufacturers have chosen to have their fixings tested and evaluated by an independent industry body to provide confidence in the product and its stated resistance values. Typically, a physical testing programme is completed and the design resistances established in accordance with a recognised standard. In the UK, and for CE / UKCA marking, the analysis of results would conform to EN 1990; ICC-ES specify a similar approach.

CE Marking, or ICC-ES accreditation should give specifiers complete confidence in the product. Independent verification by a reputable organisation in the construction industry may also be taken as evidence of properly tested product – specifiers should beware if a product has no independent assessment.

Technical Data

Specifiers should exercise caution if resistance data is presented with “safe working loads”, which is an out-of-date concept in many parts of the world. For limit state design in Europe, resistances should be expressed as the “design resistance” or the “ultimate resistance” so that designers are absolutely clear that these resistances should be compared to the design actions.

Resistances expressed using the correct terms and in the correct units are an indication that the manufacturer has appropriate technical knowledge. It would normally be expected that fasteners have resistances in shear, tension, combined shear and tension, and bearing. In addition to the design resistances, the technical data should include appropriate references to the base material from which the components are manufactured.

Blind fixings often have particular limits on internal clearance, on minimum spacing and on grip lengths, in addition to the usual data covering hole diameters and tightening torque. This data should be clear and unambiguous – a further indication of a responsible manufacturer.

Product Accreditation and Assurance

The highest standards are CE Marking and ICC-ES accreditation. Either of these endorsements should give specifiers the essential reassurance to use the product with confidence. After CE Marking and ICC-ES accreditation comes independent testing by a reputable industry body. In all cases, the physical testing should have been carried out independently of the manufacturer, and the analysis of the results to determine the design resistances should follow established procedures such as those laid out in EN 1990. A reputable manufacturer should be willing to make supporting evidence, such as formal assessments and accreditations, available to specifiers.

An Assured Product – What Else?

If the product is accredited, or has been independently tested, and is appropriate for the application, the two remaining issues are availability and price. Many manufacturers have an efficient supply chain via a distribution network throughout the world. As fasteners are relatively small, air freight is possible in special situations but will inevitably incur an additional charge.

Finally price – always important, but only a deciding factor once satisfied that the product has been accredited, or rigorously tested, has reliable design resistances and is appropriate for the application.

Looking For the Ideal Fastener? Discover The Benefits of Using a BlindBolt by Checking Out Our Guide

Would blind bolts work for you? Discover what blind bolts are and the benefits of using them by checking out our guide here.

You can also get in touch with a member of the highly-experienced BlindBolt team today by using our quick and easy contact form below. Alternatively, you can contact our team today on +44 (01299) 272 955 or by emailing us at enquiries@blindbolt.co.uk.