What Is a Blind bolt & What Is It Used For?

Blindbolt UK | 6th August 2020

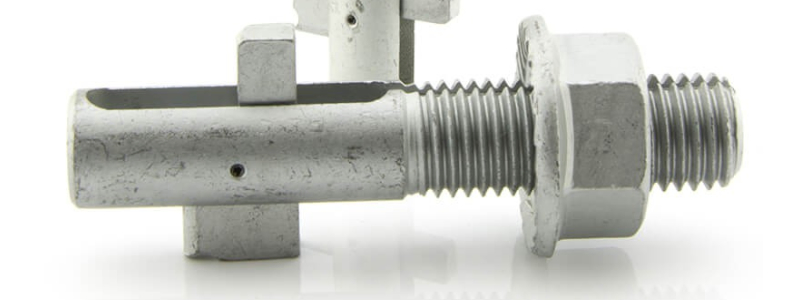

Blind Bolt

When you need a structural fastener that is stronger than rivets or welds but also adaptable; look no further than a blind bolt. Typically, you will find that structural fasteners are used to help create structures like bridges and buildings through steel to steel connections in girders and plates etc. In this blog, we will look into what a blind bolt is and how it is used.

What is a Blind bolt?

As you would expect from the name, you can use a blind bolt to create a fastening from one side through pre-drilled holes without having to access the other side to complete the lock.

A blind bolt consists of three things, a steel pin, a collar and a sleeve. When tightening the blind bolt, the collar creates a pressure that collapses the expander on the blindside while the sleeve collapses to create a seal in the visible side of the blind bolt. As well as being strong and providing a lasting connection, blind bolts are also easy to install and inspect; making them a popular choice for applications like construction where they are used to hold steel girders together.

What Is A Blind Bolt Used For?

The reason blind bolts were developed was to forge strong connections where standard hex bolts or rivets can’t be fixed due to access restrictions. Because of this, blind bolts have been the first choice when it comes to manufacturing, construction, and repairs for decades where access is restricted.

Choosing the Correct Blind Bolt

When it comes to choosing the right blind bolt for your application, you must make sure that you match the size and strength of the bolt to the job you’re doing. But how? There are several factors that you need to consider when choosing what blind bolt, you need.

Strength and Tensile Strength

The strength of a blind bolt relates to the strength of the fastener, while the grip is the total thickness of the materials that are being joined together by the fastener. The reason this is important is that the grip length of the bolt should be the distance from the underheard sur-face to the first thread of the pin shaft, and should also be a fraction less than the actual grip.

When it comes to tensile strength, it all depends on the application. This is because you want to be sure that the blind bolt you choose has the correct tensile strength and shear resistance for the task. When it comes to bolts in general, shear resistance is defined as the maximum load that is able to be supported prior to fracture, once applied to the axis of the fastener at a right angle.

The reason you want to make sure that your blind bolt has the correct tensile strength and shear resistance is simply because, if you choose a bolt that is either made of the wrong material, or too narrow, the bolt won’t last even if the initial bond is extremely strong. The reason for this is because if the bolt doesn’t match the design specifications, it could become damaged and worn quicker than those that do match the design specifications; costing you more money in the long run.

Vibration Resistance

One of the main advantages to blind bolts is that they don’t loosen during continual vibrations. This is one of the reasons why they are so popular for heavy-duty applications like bridge constructions, the creation of mining and manufacturing equipment as well as ship-building. Blind bolts can also be used in other applications where continuous vibration is a factor.

Corrosion

Blind bolts are made from various materials with many of the fasteners having an alloy steel stem, zinc-plated carbon steel collars and black oxide sleeves along with a wide range of other materials including titanium. As you may have expected, it is important that you choose the right material for your application. For example, in applications such as ship-building, where the join is exposed to a corrosive substance like seawater, you will want to choose materials that are more resistant to corrosion such as A4 stainless steel in order for the blind bolt to maintain its maximum strength for longer.

Bolted Shut

Thanks to the flexibility of the blind bolt, we are constantly finding brand new avenues where our products can save you time and money as well as increasing our range of sizes to suit your requirements.

Interested in finding out more about our blind bolts? Then feel free to get in touch and speak to a member of the Blind Bolt team today on +44 (01299) 272 955 or send us an email on enquiries@blindbolt.co.uk. We look forward to hearing from you.