The Effect of Packs in Bolted Connections

Blindbolt UK | 17th July 2023

In this article we discuss the effects of packs in bolted connections.

Load transfer

BlindBolts and HD Bolts are used as non-preloaded fixings, described as “Category A” in BS EN 1993‑1‑8. This means that shear across a connection is transferred in shear within the fixing and bearing on the fixing and on the connected plates – the fixing acts as a dowel to transfer the load. If the connected plates are in direct contact, the effect of any eccentricity between the plates is ignored.

Packs

Packing between connecting plates is sometimes required, perhaps to make up for tolerances found on site, especially if connecting to existing members. Packs may be deliberately specified to make erection easier, or as a practical way of allowing for adjustment. Packs increase the eccentricity between the load in the connected plates, which introduces some bending into the fixing, which in turn can reduce the shear resistance. Design standards specify when a reduced resistance must be calculated and provide an expression to calculate the reduced shear resistance.

Reduced Shear Resistance

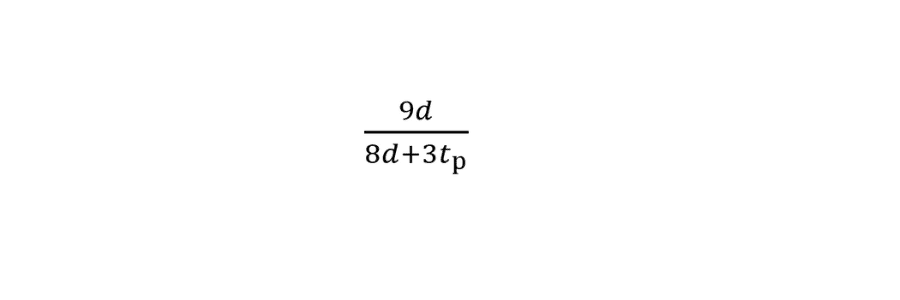

Both BS 5950 and BS EN 1993-1-8 specify the same reduction. If the total thickness of the packs is less than d/3

d/3 (where d is the bolt diameter), no reduction is necessary. If the total thickness of the packs is more than d/3, the factor to be applied to the shear resistance of the fixing is given by:

where tp is the total thickness of the packs.

Recommended practice in BS 5950

BS 5950 contains additional requirements which represent good practice and are recommended for connections with BlindBolts and HD Bolts. In BS 5950, the total thickness of steel packs must not exceed 4d/3

and no more than four packs should be used between connected plates.

BlindBolt Worked Example

The design resistance of an M16 galvanised BlindBolt is 49.1 kN over the slot.

d⁄3 = 5.3 mm, so no reduction is needed if the total thickness of packs is no more than 5 mm.

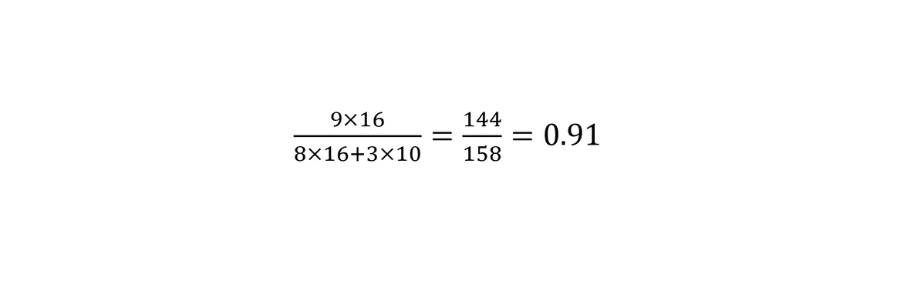

If the total thickness of the packs is 10 mm, the factor to be applied is given by:

The reduced resistance is therefore 0.91 x 49.1 = 44.7 kN

The maximum recommended thickness of packing for a M16 BlindBolt is = 4 x 16⁄3 = 21 mm

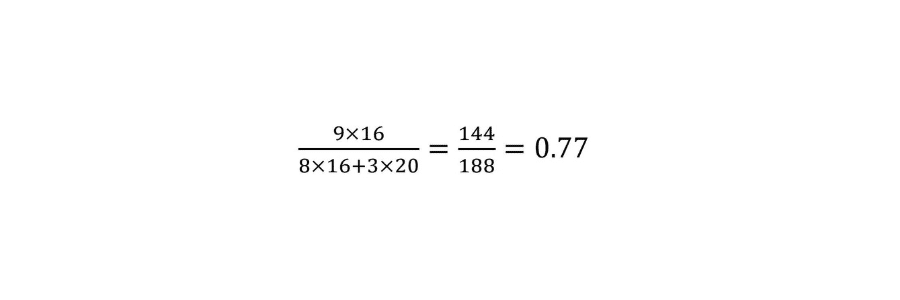

If the total thickness of the packs is 20 mm, just less than the maximum, the factor to be applied is given by:

The reduced resistance is therefore 0.77 x 49.1 = 37.8 kN

Find Your BlindBolt Today By...

... checking out our detailed guide to Blind Bolts by clicking here. You can also find out more about blind bolts by speaking to our expert team today on +44 (01299) 272 955 by emailing enquiries@blindbolt.co.uk.