Calculation Of Design Resistances in EN 1993

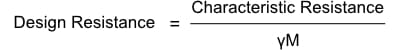

In EN 1993, a design resistance is defined as the characteristic resistance, divided by a partial safety factor, γM.

Different partial safety factors are appropriate for different components in a joint – Table 2.1 of EN 1993-1-8 refers to γM2 to γM7 with values given in the UK National Annex ranging between 1.0 and 1.25.

The situation is somewhat different in BS 5950, where the design resistance is calculated directly. Since the design resistances in both codes are very similar, the implication is that the partial safety factor is applied within the design strengths used in BS 5950, rather than being explicit.

Designers sometimes ask BlindBolt for a characteristic value of resistance for use with designs to the Eurocode, but this would require the designer to select an appropriate γM value to calculate the design resistance. The unique form of a BlindBolt is obviously different from an ordinary bolt, meaning the γM value for standardised components may not be appropriate.

For bespoke fixings such as the BlindBolt, the only reliable way to determine the design resistance is by physical test. Over a number of years, extensive testing was completed with BlindBolts in tension, in shear and in combined shear and tension, in material of different strength and thickness.

Design Resistances Determined from Test

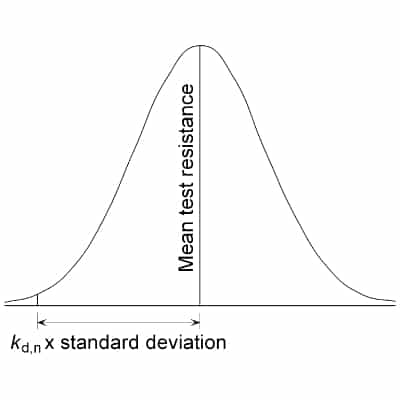

Annex D of EN 1990 facilitates the determination of both characteristic and design resistances based on test results. The basic approach is to determine the mean resistance based on a number of tests and reduce the mean value by a specified number of standard deviations. As more tests are undertaken, the number of standard deviations to be deducted from the mean is reduced.

If the design resistance is to be calculated, the reduction is a higher penalty than if the characteristic resistance is to be calculated. For example, if six tests are conducted, 1.77 standard deviations must be deducted to calculate the characteristic resistance.

A more penalising 3.33 standard deviations must be deducted to calculate the design resistance, but this approach removes the uncertainty about what value of γM should be applied to the characteristic resistance. The resistances quoted by BlindBolt are the design resistances – no partial safety factor should be applied. The quoted resistances can be compared directly with the ultimate loads on the fixing.

Shear Resistance – A Surprise Test Result

According to both BS 5950 and EN 1993, the shear resistance of a fastener understandably depends on the cross-sectional area. The shear resistance determined from test, following the procedure described above, resulted in a higher resistance than would be calculated according to the design standard. BlindBolt concluded that despite the test results, the shear resistance should be limited to the value following the expressions in the design standard, based on the cross-sectional area. In this case, the design resistances in shear follow the provisions of the design standard precisely. For designs to the Eurocode, the specified M value is applied to the calculated characteristic resistance. For designs to BS 5950, the specified strength is adopted.

BlindBolt Resistances

Resistances provided by BlindBolt are the design resistances (or “ultimate” resistances), not the characteristic resistances. There is no requirement to divide the tabulated resistances by any γM value.

Find out more by speaking to a member of our friendly, expert team today on +44 (01299) 272 955 or by emailing our team at enquiries@blindbolt.co.uk. We look forward to hearing from you soon